Software Based Inspection Solutions

Software Based Inspection Solutions

- BeamTool 10: FMC/TFM Technique Design Tools

- Assisted Analysis Software: Platform for UT Data Analysis

Software: Advanced FMC/TFM Technique Design Tools

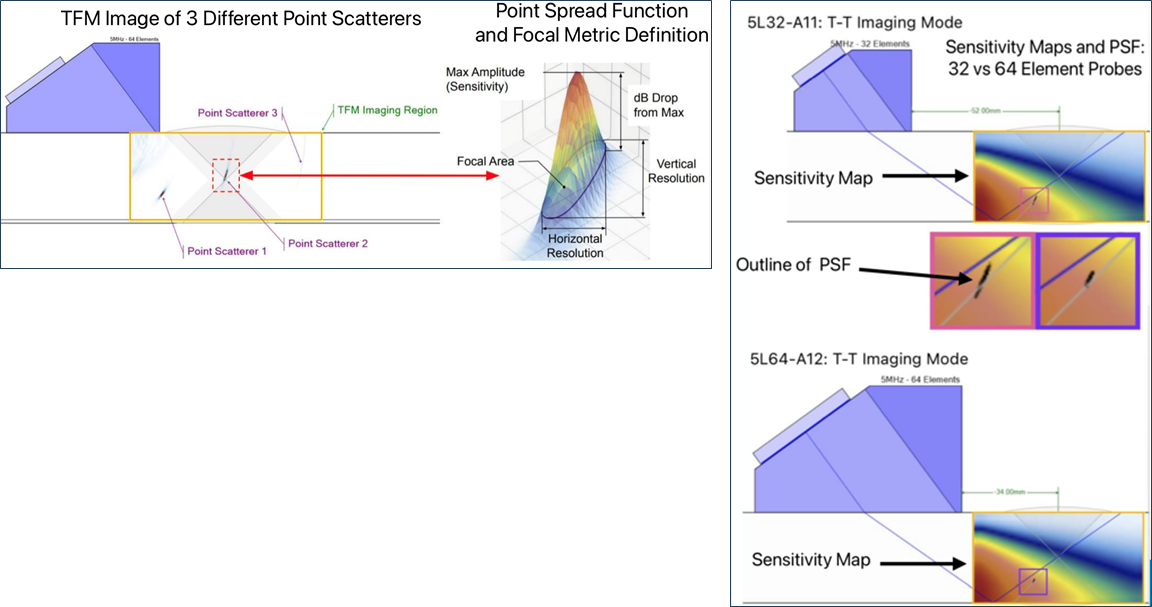

- Added functionality to Eclipse Scientific’s BeamTool software to optimize FMC/TFM based technique design

- Fast simulation of TFM image of small “point” target throughout imaging domain – so called Point Spread Function (PSF)

- Size, shape and amplitude of PSF mapped throughout chosen imaging region, quantify how well focused TFM image will be

- Helps to estimate expected sizing accuracy of technique

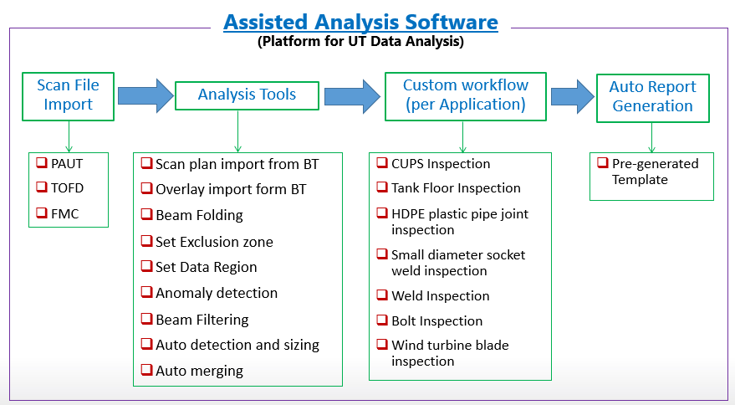

Software: Assisted Analysis Platform

- Software Platform to leverage developed post processing algorithms (ex. Shannon information processing) for custom and standard inspection applications

- Minimizes operator’s errors (missing indications, false calls) specifically for inspections with challenging geometries

- Decrease analysis time ideal for general Weld Inspection for large inspection campaigns

Assisted Analysis Platform – General Weld Inspection

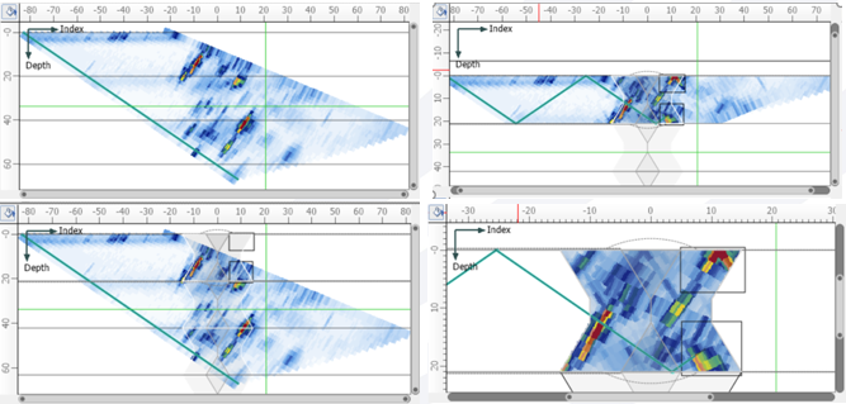

- Software for semi-automated analysis of ultrasonic data

- Corrected to geometry views (folding) with correct overlay imported from BeamTool

- Excluding data outside of regions of interested (weld volume & HAZ)

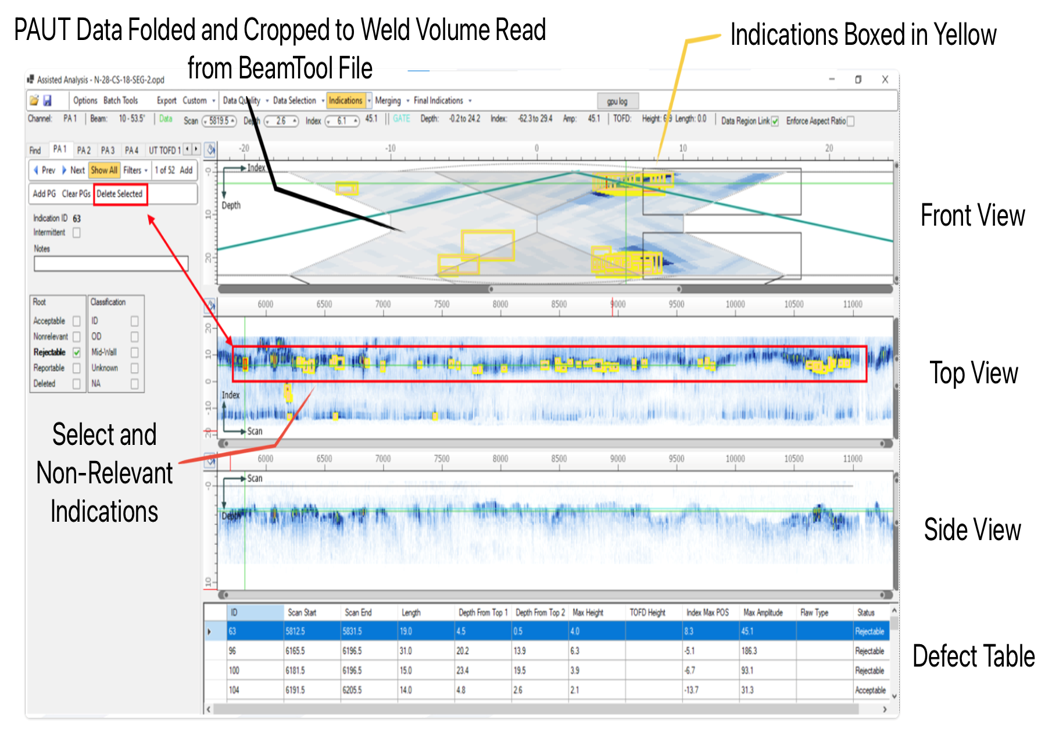

Assisted Analysis Platform – General Weld Inspection

- Common codes (ASME, ISO, AWS) algorithmically for detection and sizing, acceptance criteria automatically applied, defect table generated by software

- Analyst reviews software generated defect table, remove false calls and geometric indications

- Reports auto-generated

- Merged projection views, polygon image gating and beam folding for complex geometries supported

- Anomaly detection (Shannon Information) view implemented, limit false calls

- Up to 5 x time savings in analyzing scan files

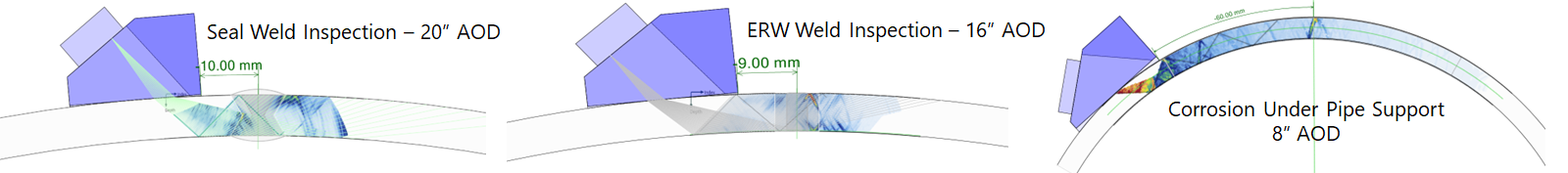

Assisted Analysis Platform – Beam Folding for Inspection in Axial Direction

- True to geometry folding facilitates analysis for characterization and sizing

- Provides major advantage for seam weld/ERW weld inspection

- Removes imprecision in positioning flaws through wall on axial pieces

Highlights of Projects

Phase Coherence Imaging (PCI) Based Applications

Application Based On Auto Highlighting Scan Data Anomalies

FMC/TFM Based Inspection Applications

Phased Array Based Inspection Applications

Wind Turbine Blade and Main Shaft Inspection Applications

Contact our experts today!

Contact Acuren