Executive Summary

Our client operates multiple steelmaking coal mining facilities, each requiring ongoing maintenance due to aging assets. Given the high cost of shutting down operations, they needed a rapid and cost-effective solution for coal silo repairs.

Since 2020, Acuren Engineering and Inspection, in collaboration with Tacten, has executed successful silo repair plans, including:

2020-2021 Silo lining repair

2022 Another facility’s Silo #2 truss refurbishment

2023 Additional silos refurbishment

By leveraging innovative repair techniques such as rope access and V-Deck, the client achieved significant time and cost savings—culminating in an estimated $15.0M in savings on the final silo project. In 2023, Acuren and Tacten services expanded as the client leveraged the integrated services approach.

Customer Problem

- Client has aging infrastructure, specifically clean coal silos, that need substantial refurbishment including lining and truss repairs.

- Prior repairs had not met the customer’s quality and cost expectations. Previous contractor’s quality of work created future repairs, unplanned downtime, and rework.

- Access to the coal silos is limited to plant shutdowns, and the daily cost is substantial.

- Silo number four is critical for coal delivery, with shut down costs of $3.2M per day.

- Coal Miner requires the shortest timeline, most cost-effective approach to complete repairs inside the coal silos

Acuren/Tacten Solution

- Acuren and Tacten combined to refurbish four coal silos

- On the initial three silos significant savings were realized from an integrated team approach utilizing engineering, alternative access including rope access and VDeck suspended platforms, coating and blasting and welding

Silo four was a critical path scope and through a robust process of continuous improvement, the client realized ~$15m in productivity gains and cost savings.

Technology Solutions

Engineering Solutions

Comprehensive inspection and maintenance plans

Over 60 years of mechanical integrity experience

Direct collaboration with repair crews for efficient, field-tested solutions

V-Deck Technology

Fastest installation rates for suspended work platforms

Accommodates multiple trades simultaneously

Reduces modification requirements for access

Rope Access Techniques

Efficient alternative to scaffolding and lifts

Enables access to complex high-location work areas

Improves safety by reducing worker exposure hours

Rope-Enabled Trades and Integrated Crews

Integrated teams for inspection, coating, blasting, and welding

Ability to install access platforms and perform repairs efficiently

Rapid implementation of high-altitude repairs

Availability of local rope-access trained tradespeople

Integrated Solution

During the 2020 outage Acuren completed inspection and an engineering remaining life assessment on a coal silo.

Tacten utilized this engineering assessment to develop a repair and execution plan. This plan reduced the outage window, total headcount, number of vendors, and overall cost to our client.

In June 2021, Tacten successfully completed the silo repair scope consisting of of the removal and replacement of wear plates inside of the coal silo

This project was foundational in shaping the client’s understanding of Tacten and Acuren Integrated Solutions capabilities, which facilitated discussions with other client sites.

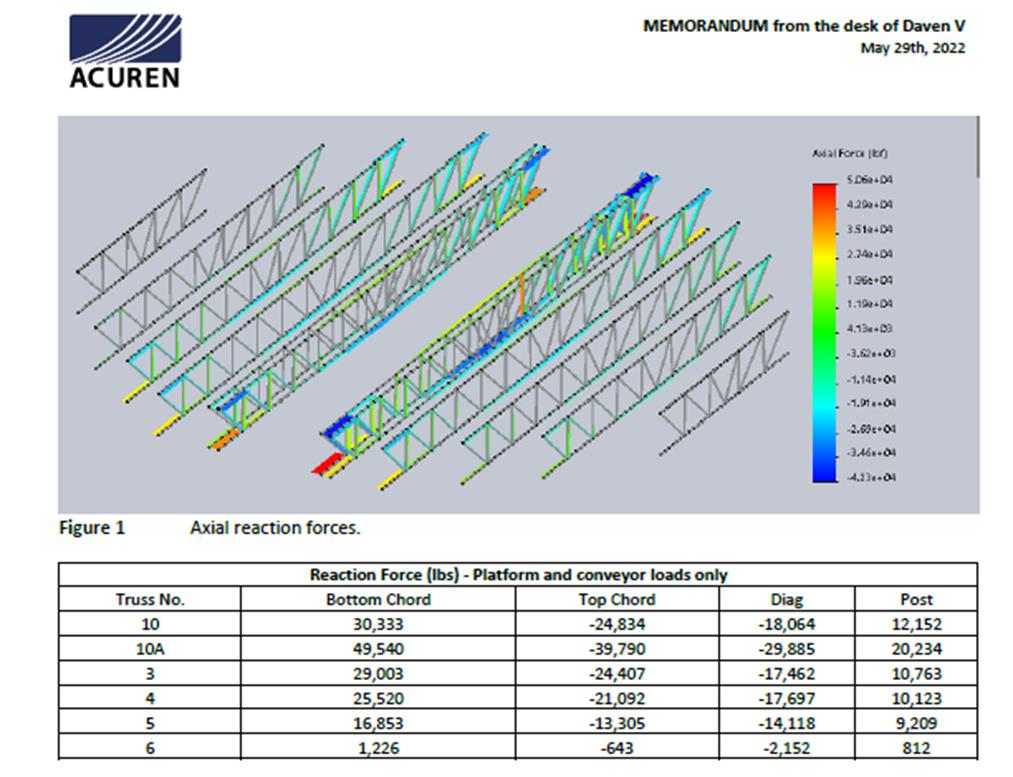

In 2022, Tacten was awarded the mechanical repair scope in another silo. The primary scope consisted of cleaning, inspection, and repair of roof trusses which had decayed over time

Acuren was able to utilize engineering and inspection capability to determine a full repair plan for the roof truss

- VDeck was critical as it allowed for limited anchor points with a shortened installation window. The limited anchor points meant minimal modifications when cleaning, repairing, and coating.

The project saved our client 18 days and an estimated $500k from traditional access methods.

Following the project, a Tacten planner remained at the client site as well as several mechanical services technicians, to perform welding repairs.

Continuous Improvement

Initial silos yielded significant savings from an integrated team approach utilizing engineering, alternative access (rope access and V-Deck), coating, blasting, and welding.

Lessons learned from previous silos allowed for an expedited project timeline on the final critical silo, condensing the anticipated shutdown window.

The final project was completed $600k under budget and 25 days ahead of schedule, saving the client an estimated $15M.

Conclusion

The collaboration between Acuren and Tacten has redefined the client’s approach to asset maintenance. By adopting an integrated service model and leveraging advanced repair techniques, the client has significantly reduced costs and enhanced operational efficiency.

Key Results:

$15.0M+ in savings on coal silo refurbishments

25-day reduction in repair time for the most critical silo

50% faster repair execution compared to traditional methods

Improved operational efficiency by reducing contractor dependency

This success underscores the value of strategic engineering and inspection services in heavy industry operations. As the client continues expanding its reliance on integrated maintenance solutions, future projects are expected to yield even greater efficiencies and cost reductions, ensuring long-term sustainability and productivity across all mining facilities.