Phased Array Based Inspection Applications

Anomaly Detection Based Applications

- HDPE Butt Fusion and Electrofusion Joint Inspection

- Inspection of Thin-wall Feeder Tube Welds

- Inspection of Forging Defects for Bearing Raceways

- Wind Tower Weld Inspection

- Weld Inspection at Elevated Temperatures

- Hydro Turbine Blade Inspection

- Through Cap Inspection of Fillet Welds Using Flexible Polymer Wedges

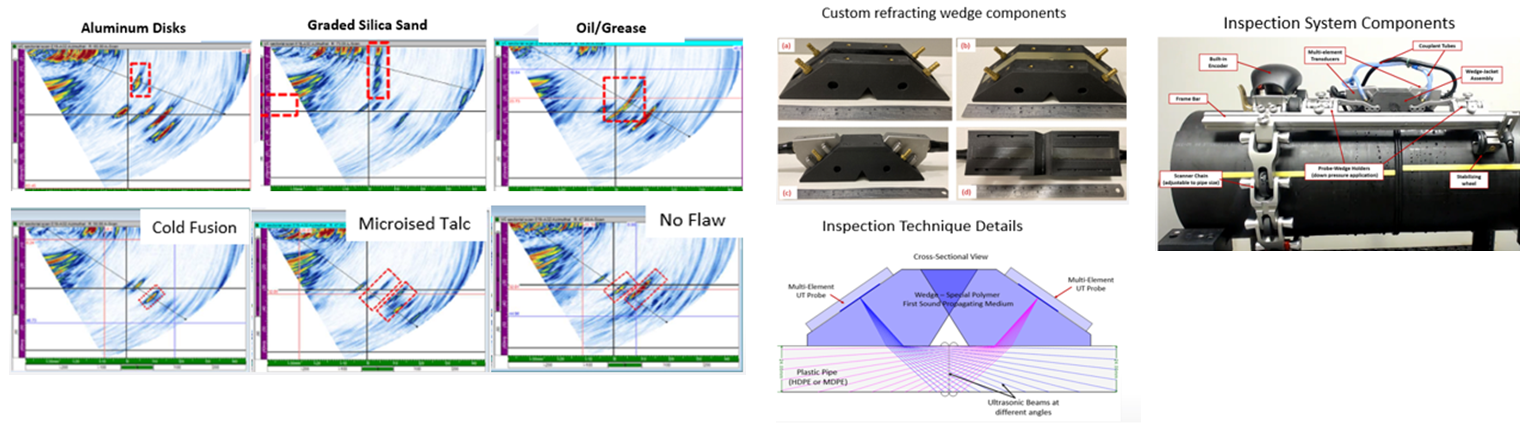

Phased Array Based Applications: HDPE Butt Fusion Joint Inspection (2” & 8” Pipes)

- Client Funded Development Projects

- Designed custom wedges with polymers with Acoustic Velocities close to water

- Inspection Technique qualified using sample with embedded real flaws

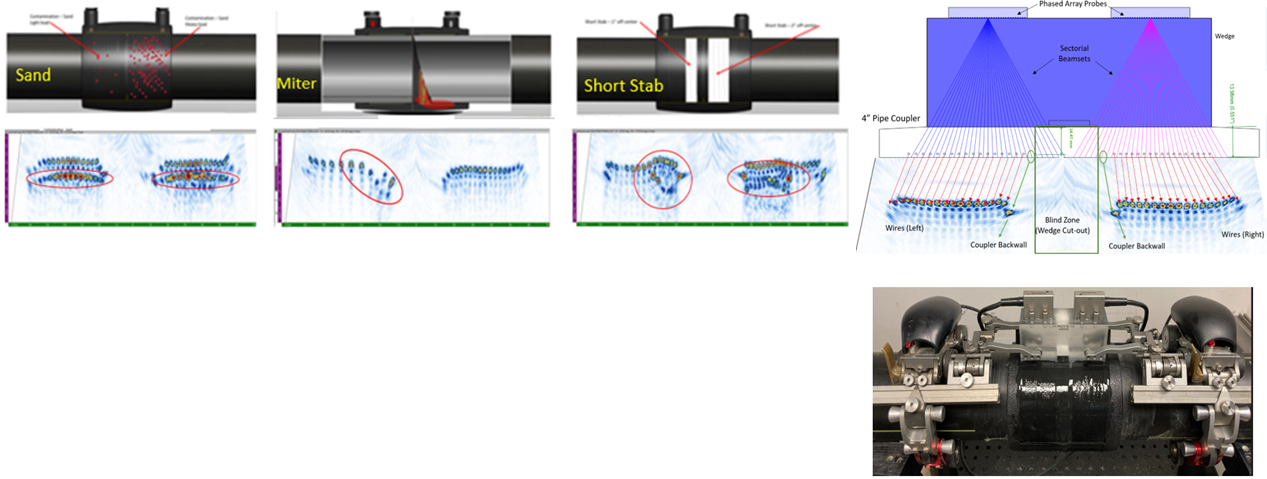

Phased Array Based Applications: HDPE Electrofusion Joint Inspection (2” & 8” Pipes)

- Client Funded Development Projects

- Designed custom wedges to detect Electrofusion Wires

- Inspection Technique qualified using sample with embedded real flaws

Phased Array Based Applications: Inspection of Feeder Tube Welds

- Contracted to develop code compliant PAUT procedure for feeder tube weld inspection (in lieu of RT)

- Inspection complicated by thin wall and tight OD curvature

- Extensive simulation used to optimize technique parameters

- Qualified technique with 95% POD on planar defects with only 4% false call rate

- Used in factory to optimize welding procedure

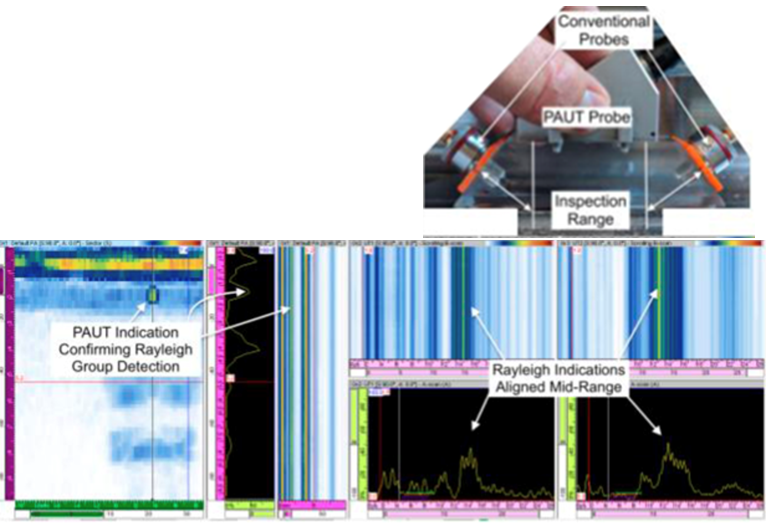

Phased Array Based Applications: Forging Defect Inspection for Bearing Raceways

- Contracted to develop inspection for near surface (0 – 3 mm deep) forging defects in bearing raceways

- Devised hybrid inspection process: highly focused PAUT inspection for 1 mm – 3 mm deep flaws plus Rayleigh wave inspection for 0 – 1 mm deep flaws

- Custom wedge designed to match curvature of raceway surface/house PAUT and Rayleigh wave probes

- Provided procedure and training materials

- Currently in use for quality control

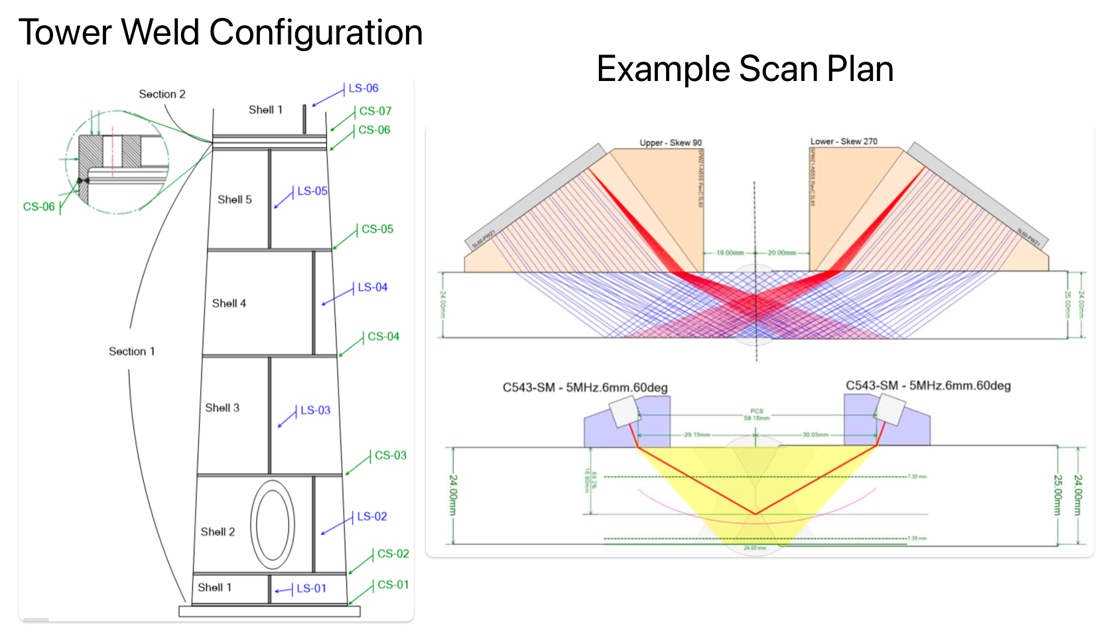

Phased Array Based Applications: Wind Tower Weld Inspection

- Contracted to develop procedure for ISO code compliant inspection of wind tower welds

- Scan plans provided for dozens of weld unique weld configurations (both PAUT and ToFD)

- Compoud scans were used instead of sectorial scans to minimize number of set-ups required

- Remote training of international crews provided

- Remote auditing of data quality and analysis results ongoing

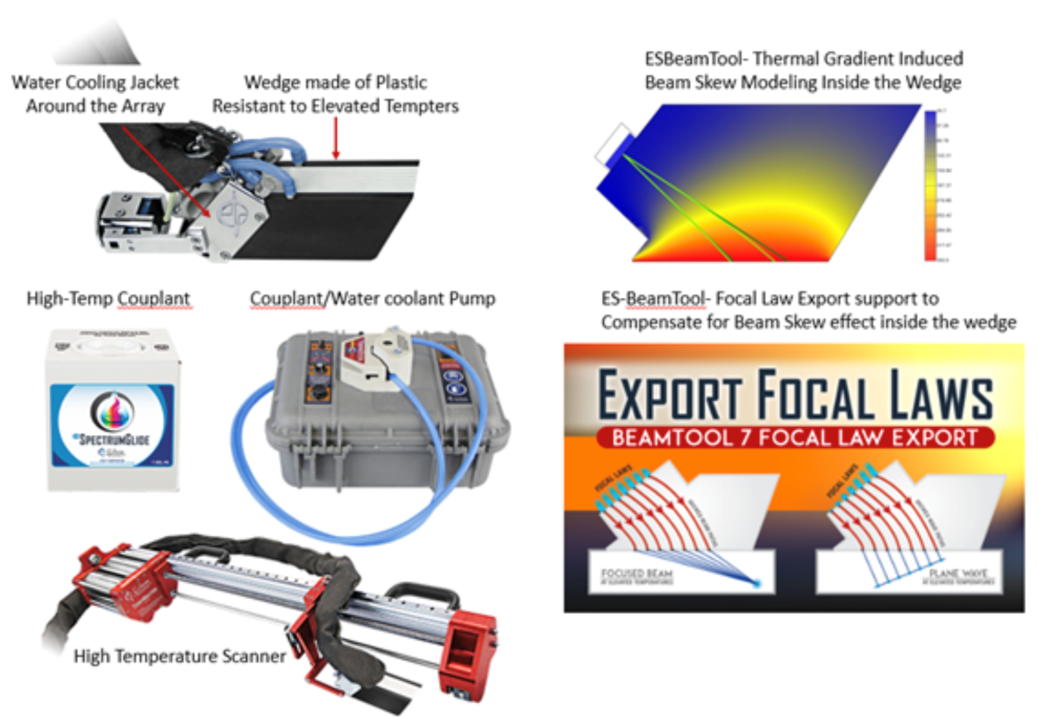

Phased Array Based Applications: High Temperature Inspection

- Developed phased array inspection system operating up to 350°C

Wedge, cabling, cooling jackets, couplant engineered to withstand elevated temperatures

Positioning errors and degradation in focusing due to temperature dependent velocity gradient corrected by custom focal law exports

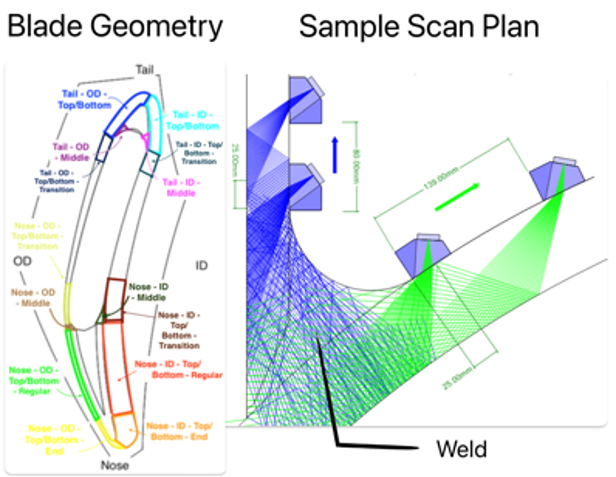

Phased Array Based Applications: Inspection of Hydro Turbine Blades

- Contracted to develop inspection procedure and calibration process for large hydro turbine blades

- Complex components with variable curvature requiring dozens of intricate scan plans

- Long travel paths required unique calibration block design

- Procedure used to perform ongoing inspections of newly welded components

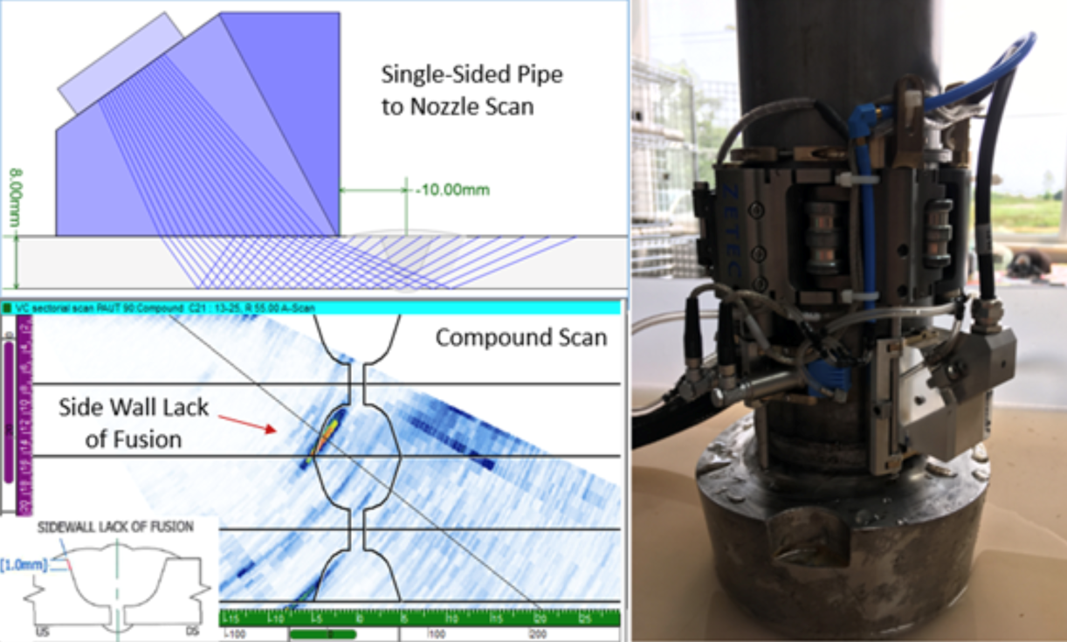

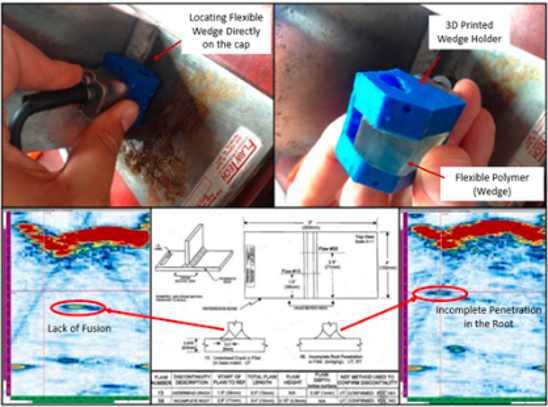

PAUT Based Applications: Through Cap Inspection of Fillet Welds Using Flexible Polymer Wedges

- Technique developed using wedges made of flexible polymers to scan directly through the weld cap

- Focused ultrasonic beams (along nominal fusion faces and the center of weld) used for detection of fusion and volumetric defects

- Acceptable coupling achieved using a thin couplant layer pressed between the weld cap and the flexible wedge material

- Technique demonstrated by detection of incomplete weld penetration and crack like defects

Highlights of Projects

Phase Coherence Imaging & Custom Ultrasonic Imaging Techniques

Application Based On Auto Highlighting Scan Data Anomalies

FMC/TFM Based Inspection Applications

Wind Turbine Blade and Main Shaft Inspection Applications

Software Based Inspection Solutions

Contact our experts today!

Contact Acuren