The API Inspection Summit will provide attendees with an opportunity to learn about new and existing industry codes and standards, hear about emerging trends from experts, and discuss new issues that they face.

API was formed in 1919 as a standards-setting organization and has developed more than 800 standards to enhance operational and environmental safety, efficiency and sustainability.

Visit us at booth #200

Technical Program Presentations:

| DATE | TIME | PRESENTATION |

|---|---|---|

| Tuesday August 9th | 3:00 – 3:40 PM | Solving Refinery Inspection Program Challenges with Drone Data |

| Wednesday August 10th | 10:00 – 11:30 AM | Waveform Analysis for DCVG, ACVG, CIS, and CP Surveys |

| Thursday August 11th | 8:00 – 8:40 AM | Application of API 579 Level 3 FFS Assessments to Many Types of Pipeline Anomalies and Conditions |

| Thursday August 11th | 10:30 – 11:10 AM | API 579 Level 3 FFS Assessment of Storage Tanks with Uneven Foundation Support |

Presentations Overview

3:00 – 3:40PM — Solving Refinery Inspection Program Challenges with Drone Data

Valero & Acuren

Presenters: Valero’s Reliability and Inspection Manager Joe Nichols and Daniel Landry from Acuren

Taking real world challenges of an inspection program in the Gulf Coast region of the US and finding innovative ways to solve some of those issues using Drone/UAV Data and software integration. Using visual data more creatively for direct solutions to soil-to-air interfaces, CUI, line identification, virtual walk-throughs, and so much more. We dive into these applications and show data from a US refining site. Hear the asset owner’s perspective as well as the 3rd party service provider.

Wednesday August 10th

10:00 – 11:30 AM — Waveform Analysis for DCVG, ACVG, CIS, and CP Surveys

Acuren

Presenters: Eric Zhan and Jordan Kennedy

Indirect surveys are considered a staple for the assessment of pipeline integrity and cathodic protection (CP) system evaluations. Inspection equipment, testing procedures and analysis techniques are used in combination to determine areas with propensity for corrosion for underground piping, USTs, and AST tank bottoms. Above ground pipeline inspections are cost effective, have been proven with millions of miles of inspection data, do not interrupt pipeline operations, can inspect un-piggable pipelines (Approximately 70% of all pipelines are un-piggable), are easily and commonly correlated with other inspections, and offer a full suite of information such as: the level of cathodic protection, location of coating anomalies, condition of the coating, accurate pipeline elevation, pipeline depth, and bend radii; this can be modeled as GIS data and evaluated alongside environmental data surrounding the pipeline. All these data sets can be used in risk models to predict where corrosion is occurring or even where corrosion is likely to occur. This is the only pipeline inspection technology which can be predictive, as all others require a certain “threshold of detection.” This presentation will focus on technologies and techniques used to collect and interpret high quality inspection data and make high confidence anomaly predictions.

Thursday August 11th

8:00 – 8:40 AM — Application of API 579 Level 3 FFS Assessments to Many Types of Pipeline Anomalies and Conditions

Acuren

Presenters: Alex Tatarov, Arash Ilbagi, and Frank Gareau

The API 579/ASME FFS-1 Fitness-for-Service (FFS) Level 2 approach is typically used for assessing pipeline anomalies/conditions found by different types of non-destructive examination devices and tools. When the level 2 assessment fails, repair, re-rating or Level 3 assessment is to be performed. In many cases, repair or rerating are either impractical, impossible, or extremely costly so a Level 3 assessment is the only option to determine if a pipeline can continue to be operated safely without downtime. The current presentation provides an overview of successful application of API 579 Level 3 assessments for anomalies, potential defects, or conditions that have been found in steel pipelines. The examples will include:

- Ovalities

- Bulges and dents, including bullet-dents

- Lifting of pipelines containing defects

- Road/railway crossings

- Girth Welds (GW) and Electrical Resistance Welds (ERW) with crack-like indications located within different misaligned geometries

- Effects of ground movement

10:30 – 11:10 AM — API 579 Level 3 FFS Assessment of Storage Tanks with Uneven Foundation Support

Acuren

Presenters: Alex Tatarov, Arash Ilbagi, and Frank Gareau

Visual inspection of several tanks in a tank farm identified gaps in the foundation and gaps between the tank floors and the foundation. The owner judged the differential settlement and abrupt unevenness of the foundation to be a potential source of high localized stresses that could initiate failure during full tank loading. 3D laser scanning of the external surfaces confirmed the tanks were tilted at many different angles and were experiencing differential floor settlement. An API 579 Level III fitness for service assessment (FFS) of the tanks was performed that included finite element analysis (FEA) and calculations of the shape and stress distributions. FEA calculations were performed for five different load cases, including voids or gaps in the foundation. The load cases included:

- Gravity load

- Hydrostatic pressure

- Internal pressure of 16 oz

- Vacuum of 0.4 oz

- Combination of the above

The results of FEA were verified and confirmed by advanced non-destructive examination that included 3D scanning of tank floors internal surface and measurement of gaps at different tank fill levels. Maximum allowable fill levels were established for 11 tanks to allow continued operation. Monitoring and inspection requirements plus operating risks were defined. Based on the FFS and engineering assessment results, a decision was made to eventually replace the tank foundation. This replacement was performed successfully, and no tank failure occurred.

Networking Events

Monday, August 8th

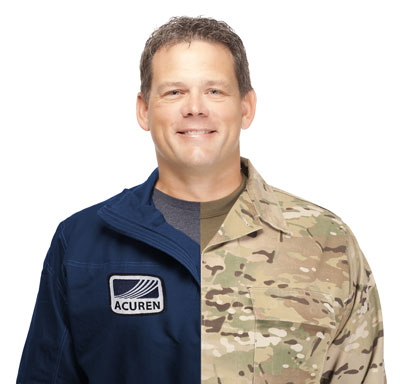

4:00 PM – Energy for Veterans

API’s ICP will host a panel discussion on how to we can prepare our country’s returning veterans for a career In the natural gas and oil industry. This session, delivered in conjunction with NextOp who will conduct the veteran outreach for the event, will describe all the ways our nation’s finest can utilize the skills they have gained in the military towards the experience needed to achieve certification In ICP. As you may know, ICP’s programs have been authorized by the U.S. Department of Veteran Affairs to allow active military, veterans and eligible spouses and dependents to utilize GI Bill® benefits to assist with the costs associated with securing a certification under one of the 21 programs in ICP. ICP Is also allowing military experience as a substitute for the educational requirements in many of its programs.

API’s ICP will host a panel discussion on how to we can prepare our country’s returning veterans for a career In the natural gas and oil industry. This session, delivered in conjunction with NextOp who will conduct the veteran outreach for the event, will describe all the ways our nation’s finest can utilize the skills they have gained in the military towards the experience needed to achieve certification In ICP. As you may know, ICP’s programs have been authorized by the U.S. Department of Veteran Affairs to allow active military, veterans and eligible spouses and dependents to utilize GI Bill® benefits to assist with the costs associated with securing a certification under one of the 21 programs in ICP. ICP Is also allowing military experience as a substitute for the educational requirements in many of its programs.

This session will be immediately followed by a networking reception.

5:00 pm – 7:00 pm – Proud Sponsors of: Women in Mechanical Integrity Workshop and Networking Event

We look forward to engaging with you! If you would like to connect with us ahead of the conference, please reach out to us by clicking here