High Energy Piping Programs & Solutions

| HEP Process Matrix | |

|---|---|

|

Why have a HEP Program?

|

|

Evaluation of Current Program

|

|

Steps for Developing a HEP Program

|

|

Program Implementation

|

|

Damage Mitigation and Repairs

|

|

Program Maintenance, Review, Continuous Improvement

|

| WHY ACUREN? | ||||

|---|---|---|---|---|

|

||||

|

|

||

|---|---|---|---|

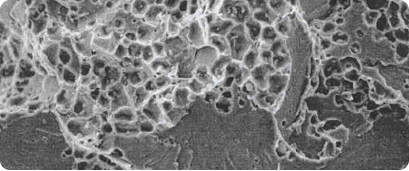

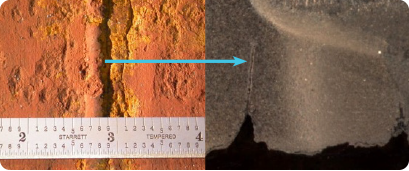

| SEM examination revealed creep voids within a weld | Corrosion-fatigue cracking in Cold Reheat Piping |

Lab analysis found corrosion fatigue cracking to be 75% through-wall |

|

Engineering Solutions & Asset Management Programs

- HEP Program Development

- Development, implementation and execution of Risk Based Inspection (RBI) programs

- In-situ & laboratory assessment to identify high temperature damage mechanisms (creep, graphitization, etc.)

- Failure analysis performed by industry experts

- Fitness for service assessments (API 579)

- Repair plan development

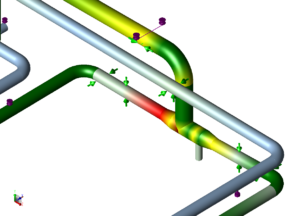

- Piping stress analysis & finite elemental analysis (FEA)

- Field measurements for strain and vibration for design improvements

- Equipment condition assessments

- NBIC/API 510/570

Piping stress analysis image to identify

areas of concern

HEP Programs target typical damage mechanisms including:

- Creep

- Fatigue

- Overload due to elevated stresses

- Flow-assisted corrosion (FAC)

- Corrosion-Fatigue

- Stress-corrosion cracking (SCC)

- Graphitization

Visual Inspection Solutions

- Remote visual options (drones, cameras)

- Experienced visual inspectors perform external inspections of equipment:

- Piping (API 570)

- Pressure Vessels (API 510)

- Boilers (NBIC, ABSA)

- Structural (CWB, CWI)

- Other

- Assess for HEP damage mechanisms

- Piping program management

- Circuitization of piping

- Develop of piping isometrics

- Selection of suitable NDE method(s)

- Selection of condition monitoring locations (CML’s)

Rope Access & Integrated Solutions

Rope Access Methods:

- Where scaffold or other means of access are not practical, Acuren can utilize rope access means to assess components

- IRATA & SPRAT certified organization

- All inspection, NDE and industrial services can be provided from ropes

Industrial Services:

- Journeyman/NCCER/PLUS certified (US) insulators

- Insulation installation/removal/repairs including asbestos abatement

- Lead/asbestos abatement

- CML ports installed

- Fireproofing

- Repairs/replacement

- Welding & fabrication

- Post-weld heat treatment

- Weld repair inspection

- Pipefitting

- Support & hanger repairs, adjustments, and replacement

Specific Techniques For HEP Programs

Broken Hanger in HEP System

- Magnetic Particle Testing (MT)

- Liquid Penetrant Testing (PT)

- Ultrasonic inspection methods

- Traditional / automated UT

- Phased Array (PAUT)

- TOFD

- In-situ metallography

- Hardness Testing (HT)

- 3D laser scanning & modelling

- Positive Material Identification (PMI)

- Infrared Thermography (IR)

- Strain gauging

- Pulse Eddy Current (PEC)

- Radiography

- Film-based

- Real Time Radiography (RTR)

- Computed/Digital Radiography (CR/DR)

Partner With Acuren For High Energy Piping Programs & Solutions

Our innovative solutions, expertise and extensive safety and quality programs help clients achieve significant cost and time savings while reducing exposure to potential hazards. We offer a wide array of services to enact comprehensive high-energy piping programs and solutions. Contact us online to get in touch with an Acuren representative about our services, or call us at 1-800-218-7450.

| RELATED SERVICES | ||||

|---|---|---|---|---|

| Laboratory Services – Inspection & NDT NDT & NDE Insurance & Litigation |

||||