FMC/TFM Based Inspection Applications

Phase Coherence Imaging (PCI) Based Applications

- Early-Stage High Temperature Hydrogen Attack (HTHA) Detection

- Early-Stage (Voiding) Creep Inspection Detection

- Thermal Shock Crack Detection

- Induction Hardness Depth Estimation & Material impurity testing (Quality Control)

- Accurate Crack Morphology Imaging and Sizing (Quality Control & On-line Monitoring)

Pioneering Industrial Applications of Phase Coherence Imaging (PCI)

- ADG instrumental in leveraging Phase Coherence Imaging approaches for challenging inspections

- Major advantages for detection of small, difficult to detect flaws/microstructural damage

- Developed statistical based dynamic range setting on images to avoid false calls

- ADG authored influential paper on using statistical interpretation of PCI data to make industrial inspection practical

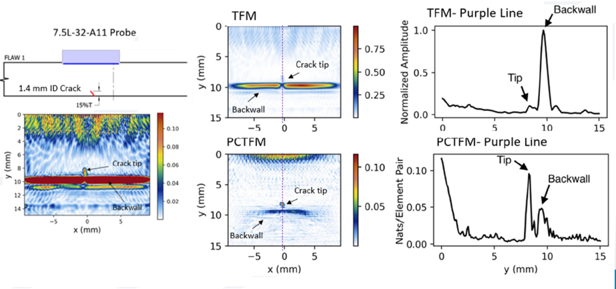

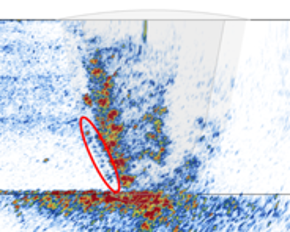

PCI – High Temperature Hydrogen Attack (HTHA)

- Phase Coherence essential for imaging earlier stages of HTHA

- Proven on verified samples (from Lavender International)

- PCTFM with automatically set dynamic range keeps from false calling grain noise

Deployment: PCI for HTHA Inspection

- Industry first HTHA inspections with phase coherence performed in January 2022 by Acuren/Eclipse

- Phase coherence imaging identified significant material impurities as well as region of possible HTHA

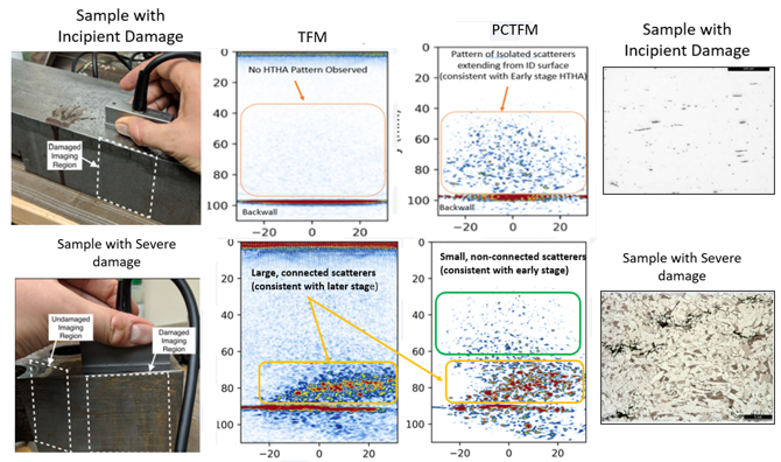

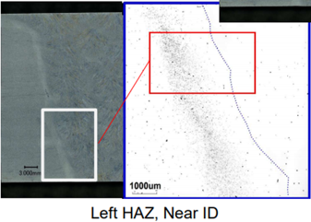

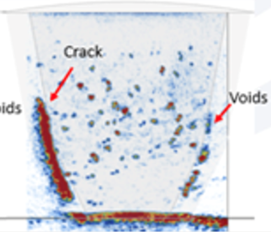

PCI: Creep Inspection

- Phase Coherence found to improve sensitivity to aligned voids, drastically improves SNR and suppress artefacts

- Proven on verified creep samples provided by EPRI

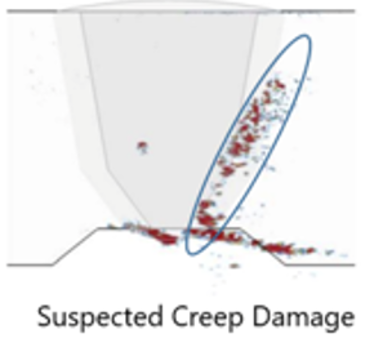

Deployment: PCI for Creep Inspection – Integrated in Acuren’s HEP Program

- Industry first creep inspections with phase coherence performed in Spring 2022 by Acuren

- PCI found to facilitate detection of creep damage and distinguishing between creep voids, material microstructure and manufacturing flaws

PCI for Thermal Shock Crack Inspection

- Thermal shock cracks are difficult to detect: tight, variable orientation

- PCI found Sensitivity to some cracks verified by destructive testing

- Field inspection performed at client site, report submitted to TSSA in support of fitness for service assessment

- Components to be monitored with phase coherence going forward

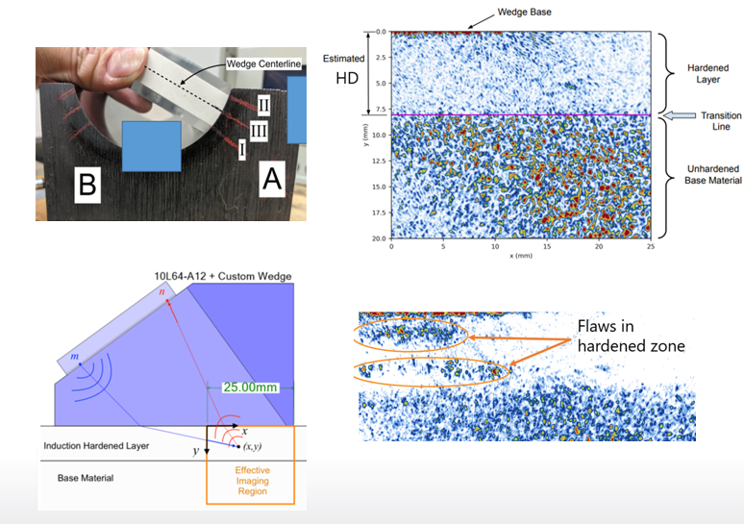

PCI for Quality Control Applications: Induction Hardened Depth Estimation

- Developed improved method to measure hardened depth on raceways for SGRE

- Grain noise contrast on PCTFM image used to automatically compute HD

- Technique also found to be sensitive to flaws in hardened zone

- Currently developing prototype for Siemens Gamesa Renewable Energy for in factory inspections (2024)

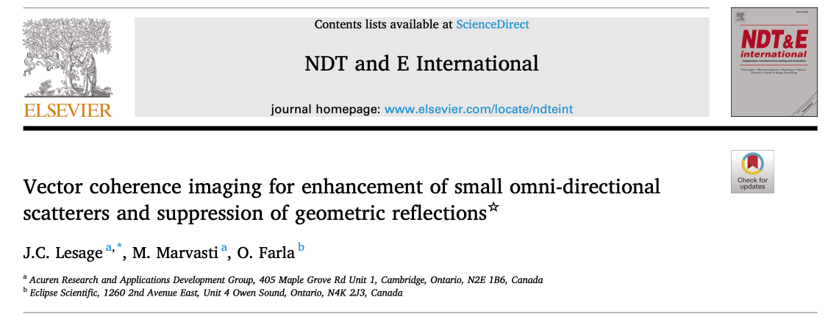

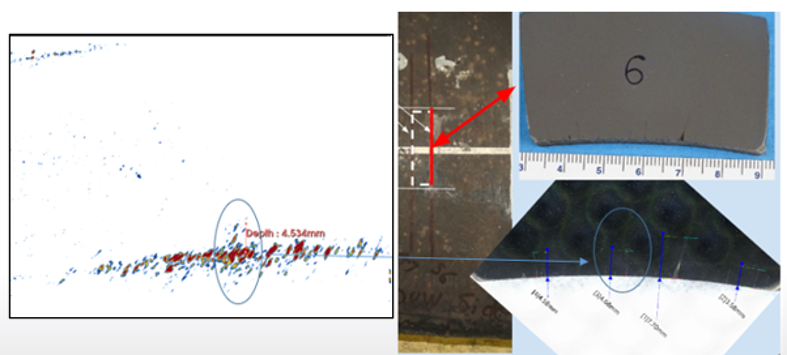

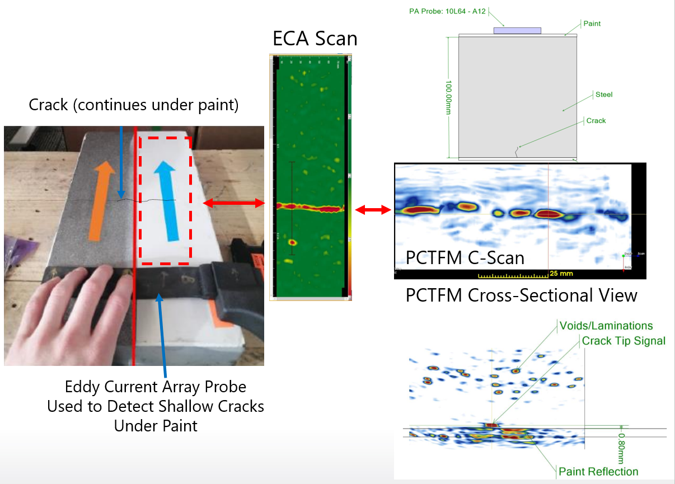

PCI for Quality Control Applications: Accurate Crack Sizing

- Long, shallow cracks in bulk plates, cannot be inspected after painting

- Eddy current array can detect but cannot depth size cracks

- Cracks tolerable up to specific depth (1.3mm), need way to measure accurately

- Cracks detected by ECA accurately depth sized via tip diffraction (not feasible with TFM)

- Depth sizing accuracy verified to be within 0.2 mm

- To be implemented by client for in-factory inspections starting in 2024

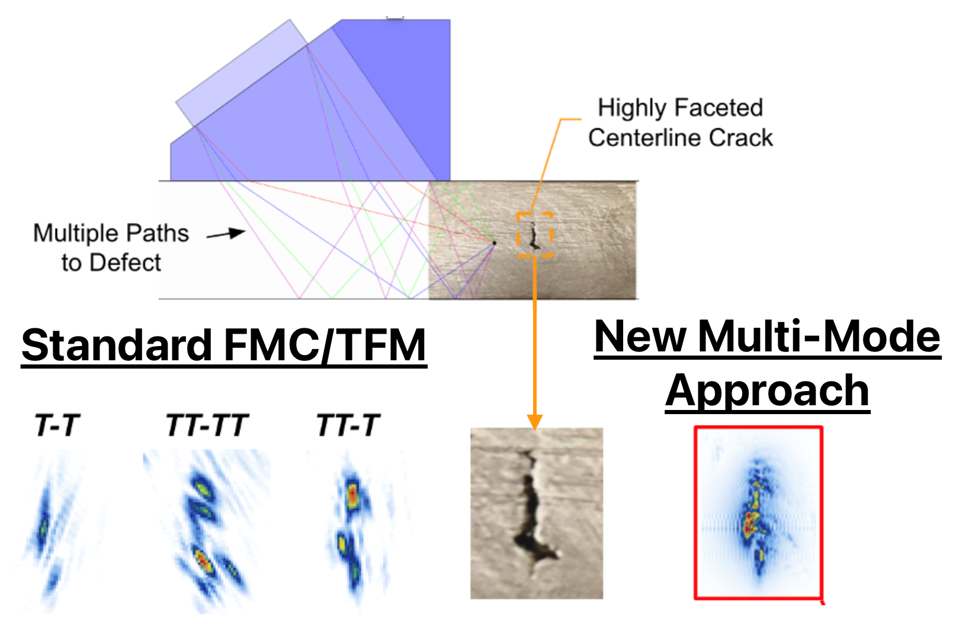

Multi-Mode Phase Coherence Imaging Algorithms

- Mutli-mode PCI method merges results from all viable modes into a single high-resolution image

- Cracks often easy to detect but hard to size, position, characterize (even with advanced methods)

- Multi-mode PCI is ideal for accurate sizing and imaging crack morphology and orientation

- Ideal for accurate monitoring of crack progression to avoid shutting down too early

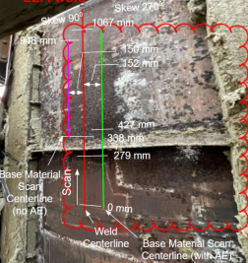

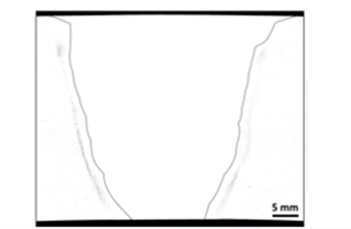

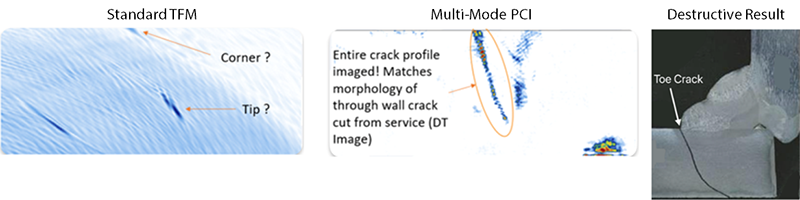

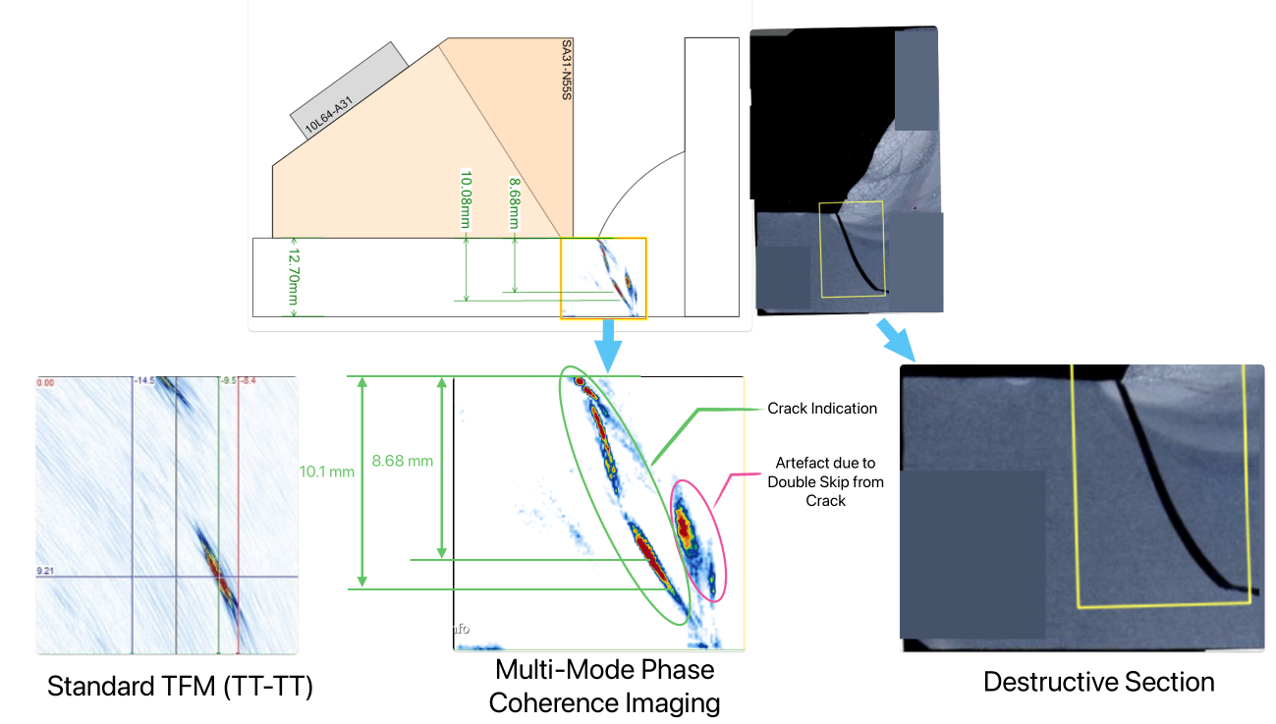

Deployment: Multi-Mode PCI for Characterizing Critical Flaws in Nozzles

- Critical toe crack inspection performed for client

- Difficult to confirm if flaw is toe crack from standard FMC/TFM image, can only see corner and tip

- New multi-mode approach showed expected profile of toe cracks previously observed

Deployment: Multi-Mode PCI for Characterizing Critical Flaws in Nozzles

- Profile of toe crack observed with multi-mode approach, confirmed by destructive testing

Highlights of Projects

Phase Coherence Imaging & Custom Ultrasonic Imaging Techniques

Application Based On Auto Highlighting Scan Data Anomalies

Phased Array Based Inspection Applications

Wind Turbine Blade & Main Shaft Inspection Applications

Software Based Inspection Solutions

Contact our experts today!

Contact Acuren