Infrared Thermography

Our infrared thermography scans large areas fast, saving time, people, work and machinery.

Infrared Thermography

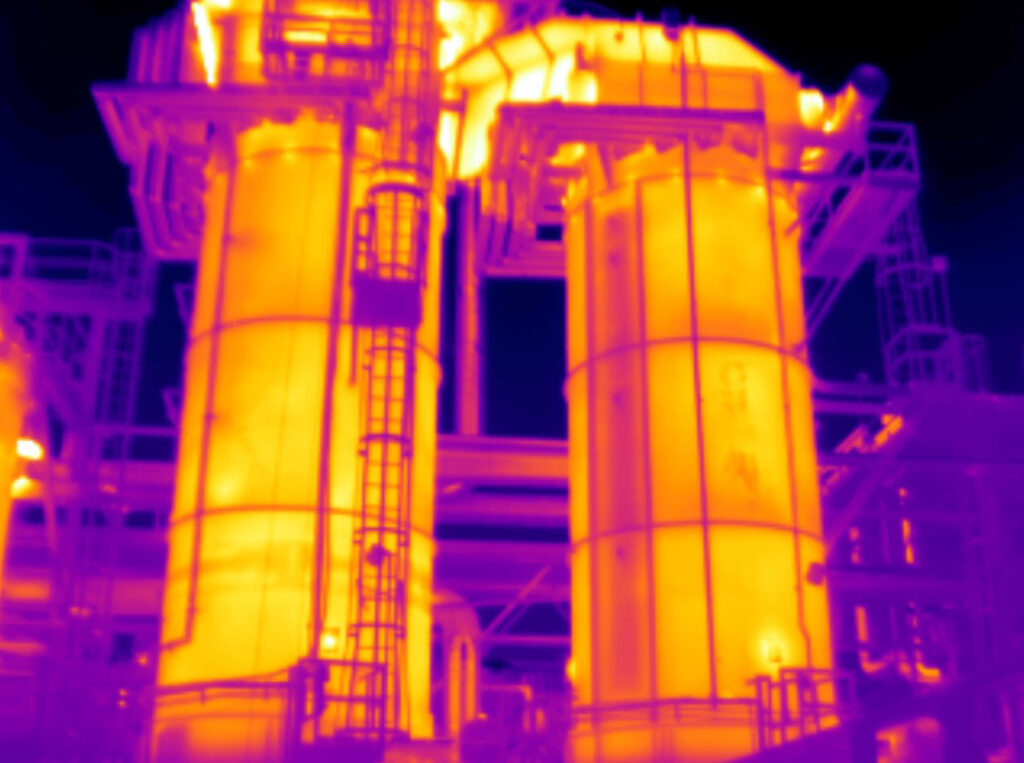

Infrared Thermography is a service that uses specialized equipment to capture the infrared energy emitted from the surface of an object and converts it to a temperature.

The data (temperature) captured from the piece of equipment is used to help analyze/determine if there has been a change in temperature and/or if it is functioning within acceptable parameters.

Most equipment failures are preceded by a rise in temperature before the failure actually occurs. This is true for mechanical, process, electronic or electrical.

It is both a visual and quantitative representation of heat being generated/emanating from a piece of equipment. The temperature can be measured over a wide area or specific location and can also be measured from a distance. It is measured in real time and can be measured for moving or static objects.

Some of the technology used for this purpose includes portable and online infrared thermometers and cameras, GasFind IR and infrared cameras for furnace scanning.

Infrared Thermography is a service that uses specialized equipment to capture the infrared energy emitted from the surface of an object and converts it to a temperature.

The data (temperature) captured from the piece of equipment is used to help analyze/determine if there has been a change in temperature and/or if it is functioning within acceptable parameters.

Most equipment failures are preceded by a rise in temperature before the failure actually occurs. This is true for mechanical, process, electronic or electrical.

It is both a visual and quantitative representation of heat being generated/emanating from a piece of equipment. The temperature can be measured over a wide area or specific location and can also be measured from a distance. It is measured in real time and can be measured for moving or static objects.

Some of the technology used for this purpose includes portable and online infrared thermometers and cameras, GasFind IR and infrared cameras for furnace scanning.

How is Infrared Thermography used?

Often used for the analysis of rotating equipment and electrical systems, excessive heat can be an indicator of a damaged or incorrect component. It can be used for both troubleshooting and as part of a predictive maintenance (PdM) program. This approach is appropriate for electrical inspections on loose connections, contactors, fuses, phase imbalance, heater coils, and breakers, etc. In mechanical applications it is appropriate for motor casings, pillow block bearings, and gearbox casings, etc. This analysis helps reduce the possibility of fires caused by overheating components and/or electrical problems. It also detects anomalies invisible to the naked eye and is a relatively low investment for quick return on investment. Return on investment is maximized when used as part of a planned maintenance route or predictive maintenance program. Consistency of time between readings and data comparison at the same location also improves ROI. Other specialized tools like the GasFind IR are used to visually identify certain types of gas leaks such as methane and hydrocarbons over large areas. Acuren also has specialized cameras that “see through the flames” for inspections on all types of gas-fired furnaces, chemical heaters or coal fired boilers and we are able to detect anomalies not captured by internal thermocouples such as overheated areas on boiler tubes. To connect directly with our reliability engineering team, please contact us at reliabilityservices@acuren.com or 1-800-218-7450.Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Field Engineering

Materials testing is brought to the field through portable techniques, including hardness testing, positive material identification (PMI), chemical spark testing, and in-situ metallography.

Learn More →Reliability Engineering

Acuren’s reliability engineering services provides world-class asset management solutions and programs to successfully reduce our clients’ operating costs through effective and proven lean maintenance strategies.

Learn More →Success Stories

Reliability Engineering Services Delivers Cost Savings

Summary Richardson Oilseed is one of Canada’s oldest and largest fully-integrated crushing, refining, processing and packaging operations. In the absence of timely manufacturer support for a critical equipment issue, the...

Learn More →Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →