Steam Cycle Chemistry Services

Steam Cycle Chemistry Services: Reduce Failures and Boiler Chemical Cleanings, Optimize Chemical Treatment Programs. Maximum Protection for the Least Cost.

Steam Cycle Chemistry Services

- Minimize Boiler Chemical Cleanings

- Reduce Equipment Failures

- Optimize Chemical Treatment Programs

- Minimize Boiler Chemical Cleanings

- Reduce Equipment Failures

- Optimize Chemical Treatment Programs

- Reduce the number of chemistry-related equipment failures

- Minimize the number of boiler chemical cleanings

- Optimize your chemical treatment program to provide the maximum protection for the least cost.

Steam Cycle Chemistry Evaluation

Our Steam Cycle Chemical Evaluation is an extensive, objective and unbiased review of a facility’s steam chemistry practices. This comprehensive assessment includes a detailed review of the following areas:- Water pretreatment equipment

- Treatment chemicals and usage levels

- Chemical operating limits

- Sampling points and sample conditioning

- On-line instrumentation

- Analytical procedures and frequency of testing

- Lay-up and startup practices

- Condensate collection and reuse

Outage Inspections

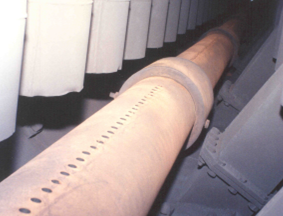

Outages are particularly important times to examine the long-term effects of chemical treatment. Acuren will inspect the feedwater system, boiler drums, and condensers. Our full-service laboratory will examine metallurgical samples, conduct tube deposit loading analysis, and provide a detailed analysis of deposits and corrosion products found in the system. Following the inspection, we prepare an outage report, which contains inspection results and photographs documenting the condition of key equipment, along with an evaluation of the performance of the chemical treatment. The report will list specific recommendations for improving steam cycle chemistry and reducing corrosion and deposits. This inspection can be combined with other services including piping surveys and inspections for mechanisms such as flow-accelerated corrosion (FAC).

Outages are particularly important times to examine the long-term effects of chemical treatment. Acuren will inspect the feedwater system, boiler drums, and condensers. Our full-service laboratory will examine metallurgical samples, conduct tube deposit loading analysis, and provide a detailed analysis of deposits and corrosion products found in the system. Following the inspection, we prepare an outage report, which contains inspection results and photographs documenting the condition of key equipment, along with an evaluation of the performance of the chemical treatment. The report will list specific recommendations for improving steam cycle chemistry and reducing corrosion and deposits. This inspection can be combined with other services including piping surveys and inspections for mechanisms such as flow-accelerated corrosion (FAC).

Troubleshooting and Incident Recovery

When contamination occurs, what is the best way forward, continued operation at reduced capacity or to shut the plant down? Acuren’s experience can help you identify and evaluate the risks to your critical equipment and make the best long-term decision for your site. After the decision is made, we can work with you to return the chemistry program to normal. We can support and work with your plant to prepare a root cause analysis, and make recommendations to prevent similar incidents in the future.

When contamination occurs, what is the best way forward, continued operation at reduced capacity or to shut the plant down? Acuren’s experience can help you identify and evaluate the risks to your critical equipment and make the best long-term decision for your site. After the decision is made, we can work with you to return the chemistry program to normal. We can support and work with your plant to prepare a root cause analysis, and make recommendations to prevent similar incidents in the future.

Training

We prepare and present professional training materials on steam cycle chemistry for laboratory, operations, and supervisory personnel. Each course is tailored to the needs and equipment of the individual facility. Our training courses receive outstanding reviews because they produce results. When workers understand why chemistry is important and what to do when out-of-limit conditions occur, chemistry-related failures decrease.Chemical Cleaning Support

Time between chemical cleanings and changes in personnel may leave you concerned about staffing your chemical cleaning with an experienced plant representative around the clock. We have helped many clients in all aspects of the cleaning process; from evaluating the need to clean, to bidding the job, to managing the actual cleaning process. We can assist you in any aspect of the cleaning or turn-key the entire project.| RELATED SERVICES | ||||

|---|---|---|---|---|

| Power Generation

Laboratory Services – Materials Testing

NDT & NDE

High Energy Piping Programs & Solutions

QUICK LINKS

QUICK LINKS

|

||||

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →