Finite Element Analysis and Computational Mechanics

Pressure Vessels, Piping, Tanks, Turbines, Industrial Equipment. FEA - A Cost-effective, Accurate Method for Evaluating Equipment and Process Interaction.

Finite Element Analysis and Computational Mechanics

- Evaluate Design Adequacy of New Equipment

- Evaluate Fitness-for-Service of Existing Equipment

- Supplement Failure Analysis to Determine Root Causes and Engineer Optimum Repair Solutions

- Provide Quick, Practical, Cost-Effective Solutions

- Evaluate Design Adequacy of New Equipment

- Evaluate Fitness-for-Service of Existing Equipment

- Supplement Failure Analysis to Determine Root Causes and Engineer Optimum Repair Solutions

- Provide Quick, Practical, Cost-Effective Solutions

The use of conventional tools to determine equipment fitness-for-service (FFS) often results in overly conservative assessments, which can then lead to unnecessary repairs, replacements, or non-optimum equipment operation. Acuren specializes in evaluating a wide range of pressure containing equipment and structures using advanced analytic techniques including linear and nonlinear, static and dynamic analyses. In addition to FEA, Acuren utilizes other advanced analytical tools to perform piping analysis, fitness-for-service, and numerical fracture mechanics analysis.

FEA utilizes a computer model of a component or assembly that is usually stressed and analyzed for specific results such as deflection or stress intensity. FEA is most commonly used for new product design or product refinement. However, using FEA to determine or verify failure scenarios is equally practical.

The use of conventional tools to determine equipment fitness-for-service (FFS) often results in overly conservative assessments, which can then lead to unnecessary repairs, replacements, or non-optimum equipment operation. Acuren specializes in evaluating a wide range of pressure containing equipment and structures using advanced analytic techniques including linear and nonlinear, static and dynamic analyses. In addition to FEA, Acuren utilizes other advanced analytical tools to perform piping analysis, fitness-for-service, and numerical fracture mechanics analysis.

FEA utilizes a computer model of a component or assembly that is usually stressed and analyzed for specific results such as deflection or stress intensity. FEA is most commonly used for new product design or product refinement. However, using FEA to determine or verify failure scenarios is equally practical.

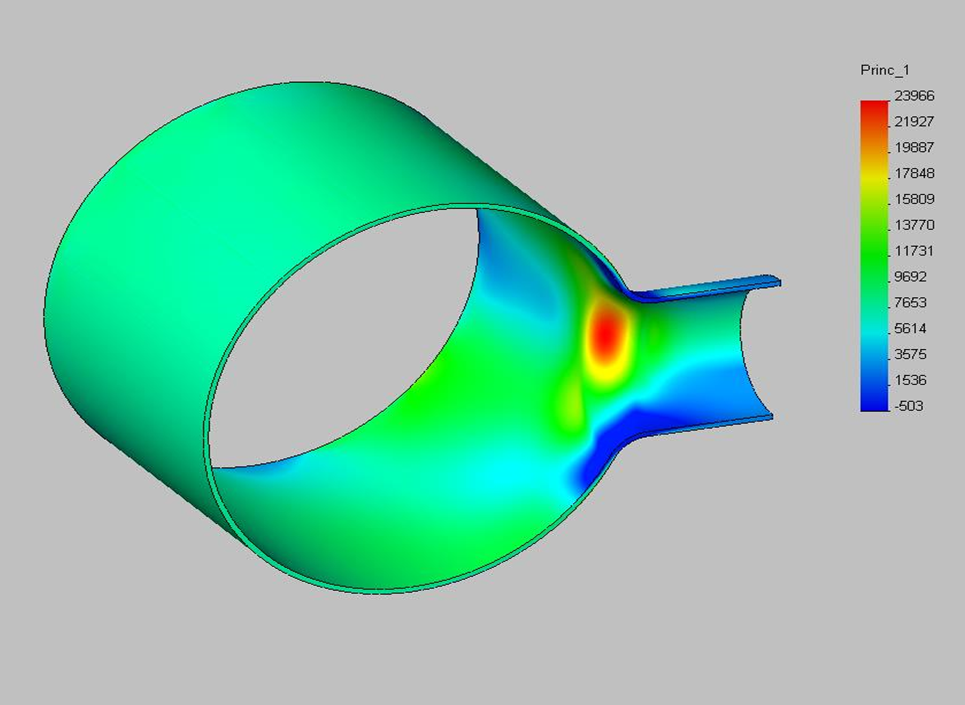

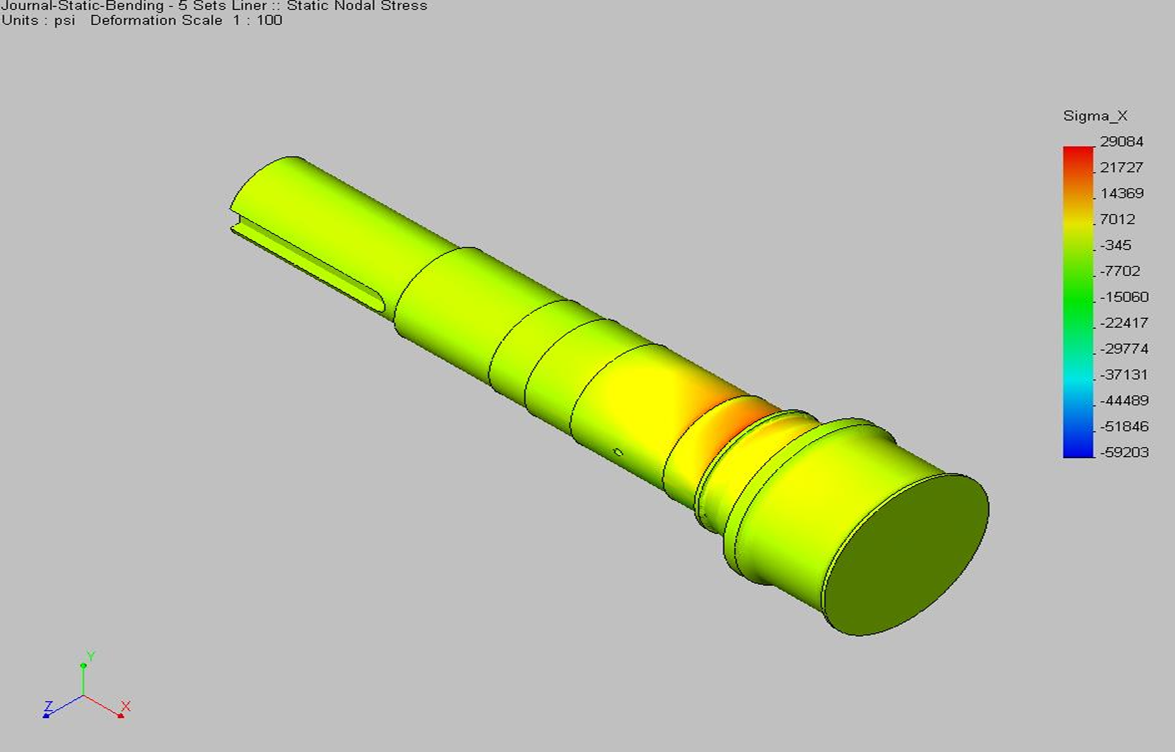

FEA can be done using 2-D modeling or 3-D modeling. 2-D modeling requires less computer resources and allows the analysis to be performed faster. However, interpretation of the data tends to be trickier. 3-D modeling requires significantly more computer resources; however, it produces results that are more visually meaningful. 2-D modeling or 3-D modeling can be either linear or non-linear.

Linear systems are far less complex and generally do not take into account plastic deformation. Non-linear systems do account for plastic deformation, and are capable of testing a material all the way to fracture.

FEA can be done using 2-D modeling or 3-D modeling. 2-D modeling requires less computer resources and allows the analysis to be performed faster. However, interpretation of the data tends to be trickier. 3-D modeling requires significantly more computer resources; however, it produces results that are more visually meaningful. 2-D modeling or 3-D modeling can be either linear or non-linear.

Linear systems are far less complex and generally do not take into account plastic deformation. Non-linear systems do account for plastic deformation, and are capable of testing a material all the way to fracture.

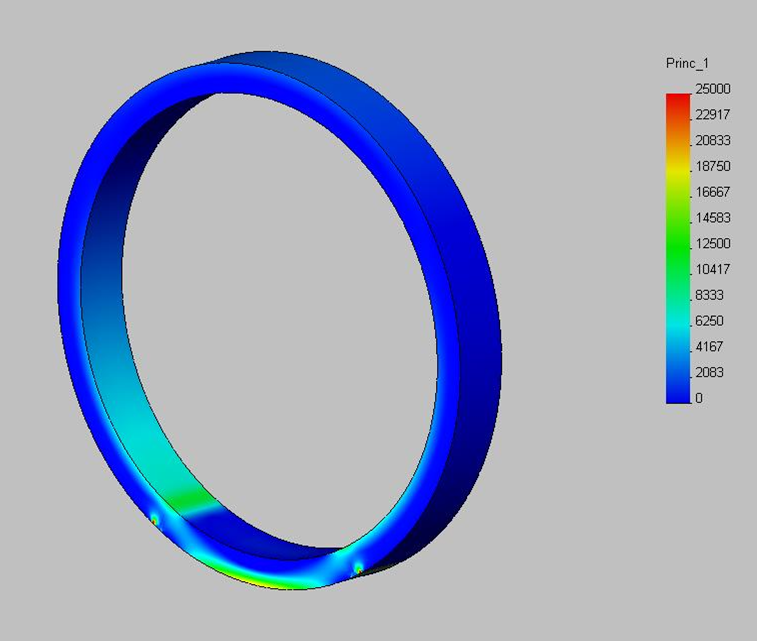

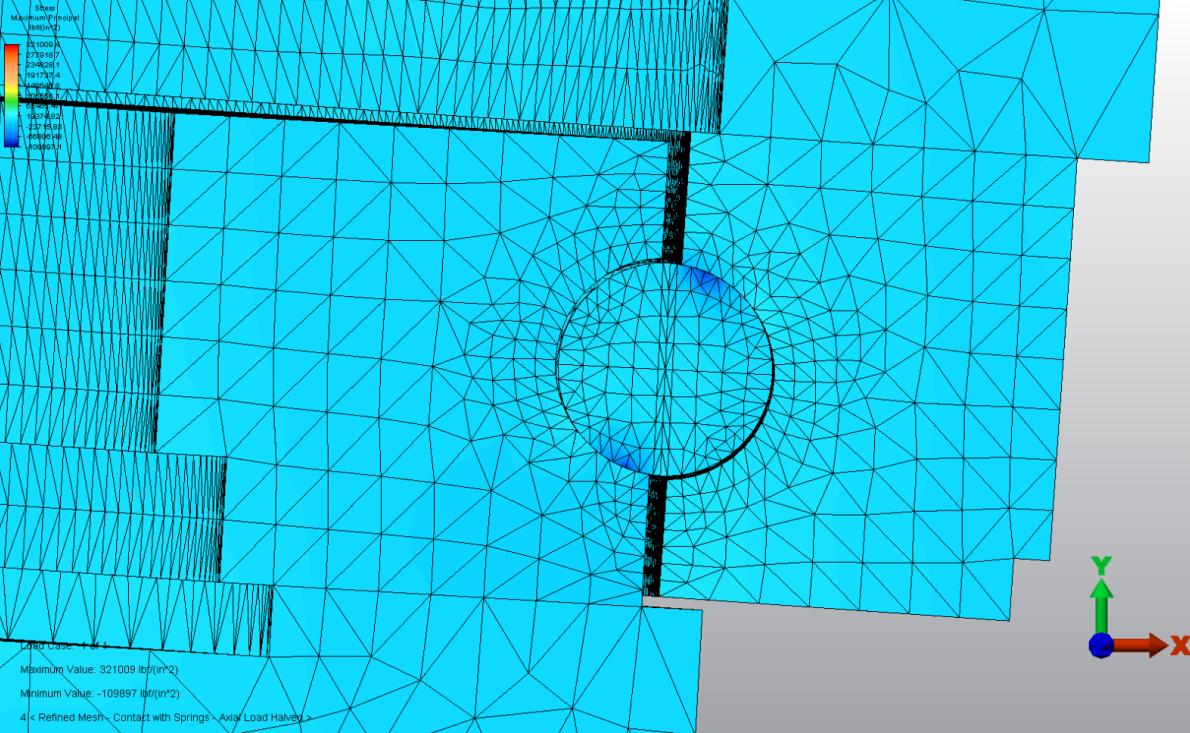

FEA uses a complex system of points called nodes which make a grid called a mesh. The mesh is programmed to contain the material properties that define the stiffness of the structure under loading conditions. Nodes are assigned at a certain density throughout the material depending on the anticipated stress levels of a particular area. Regions of higher stress usually are given a higher node density (tighter grid) than those regions of little or no stress.

There are multiple loading conditions that may be applied to a FEA model. These include point load, pressure, gravity, centrifugal loads, forced displacements, thermal loads, heat flux, and convection, all of which can either be static (constant) or dynamic (variable).

FEA uses a complex system of points called nodes which make a grid called a mesh. The mesh is programmed to contain the material properties that define the stiffness of the structure under loading conditions. Nodes are assigned at a certain density throughout the material depending on the anticipated stress levels of a particular area. Regions of higher stress usually are given a higher node density (tighter grid) than those regions of little or no stress.

There are multiple loading conditions that may be applied to a FEA model. These include point load, pressure, gravity, centrifugal loads, forced displacements, thermal loads, heat flux, and convection, all of which can either be static (constant) or dynamic (variable).

| RELATED SERVICES | ||||

|---|---|---|---|---|

| Power Generation

Laboratory Services – Materials Testing

NDT & NDE

High Energy Piping Programs & Solutions

QUICK LINKS

QUICK LINKS

|

||||

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →