Your Turnkey Solution for Corrosion Under Pipe Supports

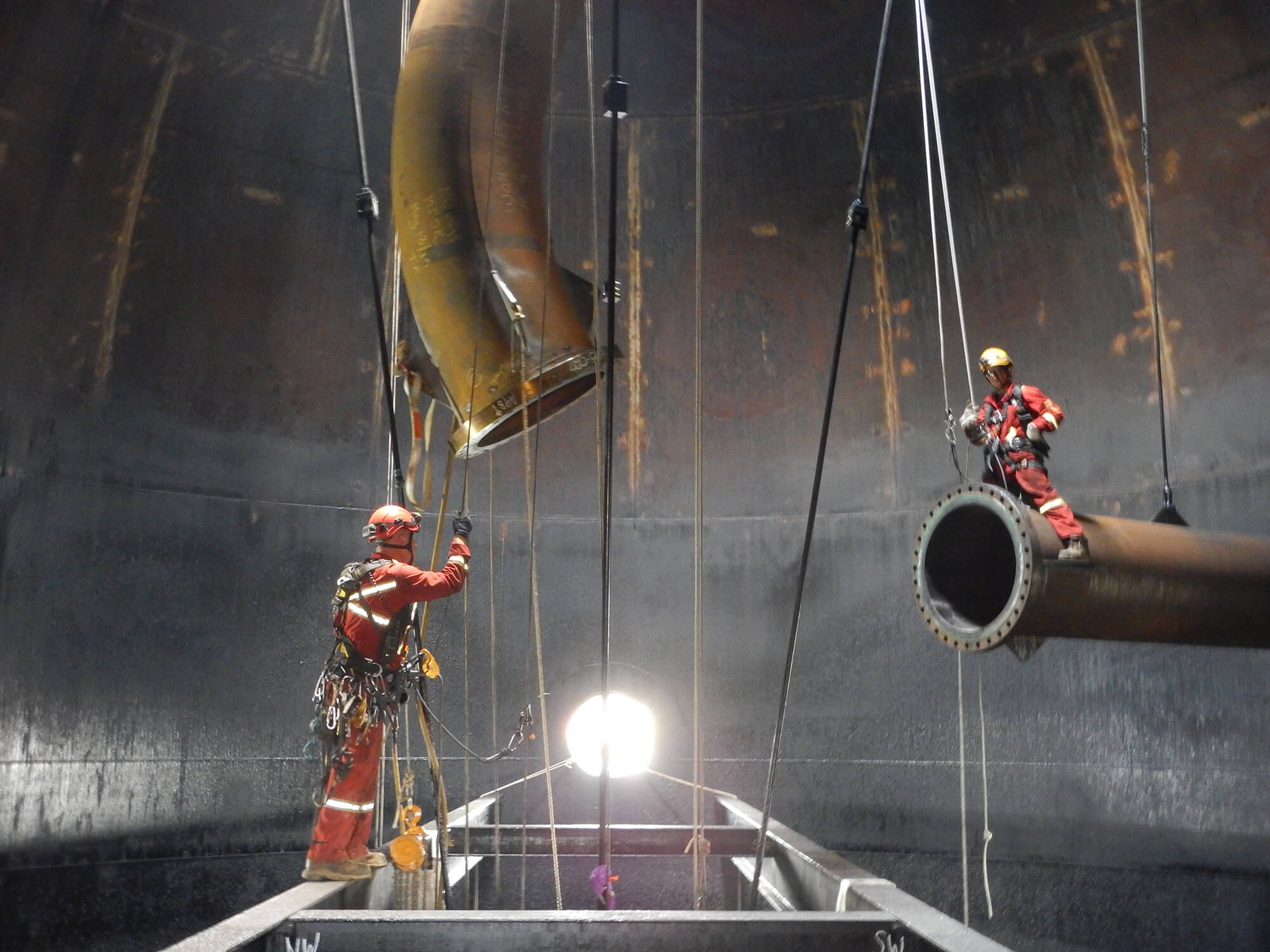

Rope Access eliminates costly scaffolding, reducing exposure hours and downtime.

Inspect / Lift / Mitigate – One provider

Start a Conversation With Our Experts

Find out how rope access can save you time and money.

Acuren is the industry leader in nondestructive testing (NDT), inspection, engineering and rope access enabled industrial services, in North America, delivering a higher level of reliability to clients around the globe. We have over 30 years of experience in the inspection industry and 14 years in rope access, making us the only provider you will need to inspect, lift, and mitigate.

Our CUPS Approach

Corrosion under pipe supports is one of the leading causes of pipe failures. It is the beam supports and saddle clamps that have historically caused the majority of problems. Poor accessibility makes it virtually impossible to paint or otherwise maintain these locations; visual and/or NDT inspection are often difficult. Don’t let the accessibility of your pipe supports keep you from timely implementing an inspection solution to avoid costly pipe failures that can affect your operation and possibly the safety of many.

Why Let CUPS Impact Your Process?

Our in-service process ensures the correct solution is personalized to fit your unique needs.

Our Promise:

Maximize your inspection and reliability while minimizing your cost, no compromise.

Our Access Solution

Pairing our CUPS services with our rope access solution enables us to access hard to reach areas without the use of scaffolding that leads to three main benefits: cost savings, reduced schedule, and improved safety. Additionally, if pipes are needed to be lifted for mitigation, our team can lift multiples pipes or select pipes across supporting structure. Our method is safe, lightweight with minimal chance to damage the pipes during lifting. It is portable, with only a 1-2 man operating, and purely mechanical. No need for power or compressed air.

More about our Benefits:

Cost Savings

|

Reduced Schedule

|

Safety

|

Inspection Techniques

|