Ammonia Systems Inspection Services

Acuren inspection services for ammonia refrigeration systems are the most comprehensive, revealing and cost effective available for insulated pipe. We offer the only inspection method that proves its results with detailed, easy-to-understand images.

Ammonia Systems Inspection Services

COMPREHENSIVE, RELIABLE NDT AND MI INSPECTION

Acuren inspection services for ammonia refrigeration systems are the most comprehensive, revealing and cost-effective available for insulated pipe. We offer the only inspection method that proves its results with detailed, easy-to-understand images.

Acuren inspection services for ammonia refrigeration systems are the most comprehensive, revealing and cost-effective available for insulated pipe. We offer the only inspection method that proves its results with detailed, easy-to-understand images.

- Non-invasive test methods won’t harm insulation or jacketing, deliver multiple readings per test location, measure pit depths and provide pipe diameter and schedule

- Real-time x-ray scans cover full lengths of pipe runs to find areas of interest for further inspection

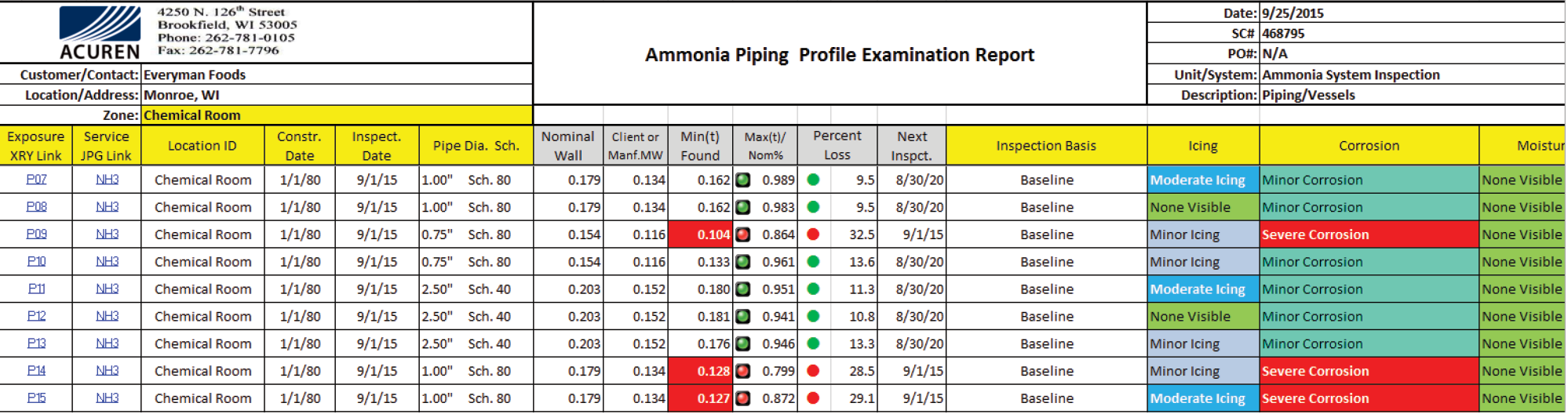

- A detailed findings report includes all wall thickness images, scan video results and all needed calculations to show wall loss percentage using customer acceptance criteria

Our mission is to provide reliable, repeatable service for every customer, everywhere, every day. As the largest provider of NDT services in North America, our depth of resources and talent is unequaled. Our ammonia system specialists can provide results that clearly identify maintenance and repair requirements, allowing you to proactively and efficiently address the needs of your operation.

Our mission is to provide reliable, repeatable service for every customer, everywhere, every day. As the largest provider of NDT services in North America, our depth of resources and talent is unequaled. Our ammonia system specialists can provide results that clearly identify maintenance and repair requirements, allowing you to proactively and efficiently address the needs of your operation.

Acuren’s non-invasive inspection methods provide conclusive, visible & cost effective results.

MECHANICAL INTEGRITY VISUAL INSPECTIONS

- A 5-year independent inspection of the ammonia refrigeration system performed by a competent non-biased 3rd party inspection service

- We conduct thorough visual inspections of all process equipment and controls utilizing the latest codes and standards

- A review of the Process Safety Management documentation to include all process safety information as well as all mechanical integrity tests and inspections procedures

THE MOST ADVANCED TESTING AVAILABLE

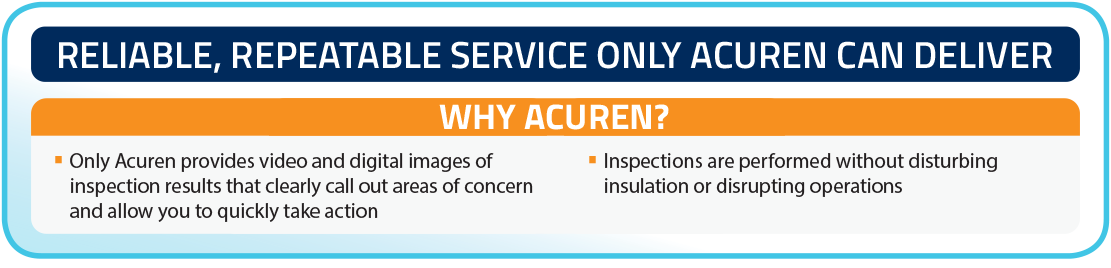

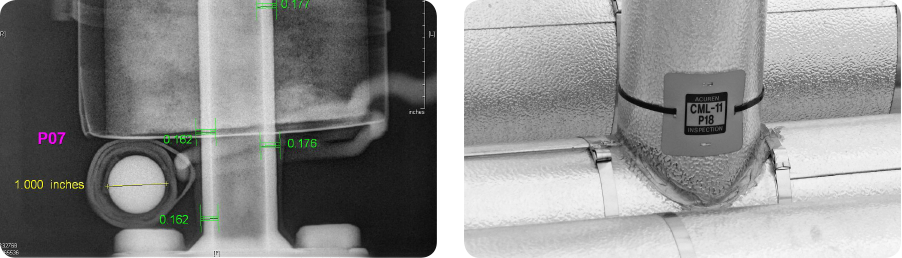

Start your mechanical integrity program off the right way. We number and tag each test location, x-ray and scan. We take location photos and assign an index page to each named facility location for easy follow-up in the report. Future inspections are easier and comparable because of our tagging and report system.

- Acuren’s Digital Radiography of insulated pipe gives clear visual proof of pipe condition

- Pipe wall thickness measurement are accurate to the thousandths of an inch

- Quickly gathered data identifies severe risk locations for immediate action

- Prevents unexpected shutdowns, product loss and safety hazards

- RTR allows our team to see the surface of the pipe in real time, throughout the length of a pipe run

- Technicians mark areas of concern indicating possible rust

- Digital Radiography is then performed to determine wall thickness

- RTR can inspect thousands of feet per inspection

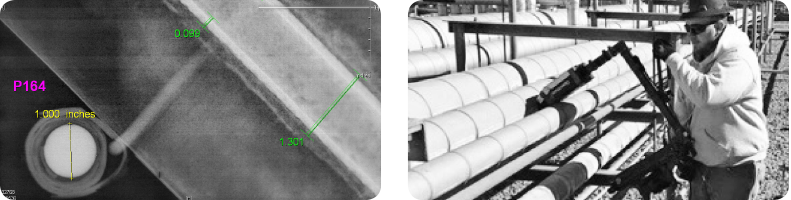

- MDI is a screening tool that helps pinpoint a saturated point of the system. Any time carbon steel pipe is in moisture, corrosion and wall loss can happen.

- These spots will be points of interest for Digital Radiography to measure

- Scan large areas quickly, examples include

- Straight Run-600m/1800ft per 12-hour shift

- Complex Piping 300m/900ft per shift

- Complex Piping with RAIS 200m/600ft per shift

COMPREHENSIVE DIGITAL REPORTING

- Contains every x-ray image with all wall thickness readings

- Contains every real time scan video showing all areas of interest

- Wall loss percentage markers reflect areas for immediate attention

- Customizable to your criteria and action plans

COMBINING COMPREHENSIVE REPORTS WITH MOBILE CAPABILITIES AT YOUR FINGERTIPS

Acuren Inspection Ammonia Services group now offers mobile access to the vital inspection report information your team needs. Empowering the appropriate personnel with critical system information will help them not only stay knowledgeable about their systems condition, but also allow them to make safe decisions that support efficient plant operation. The on demand, 24/7 access to inspection report information, both wall thickness and x ray images, can be viewed in the field at the point of inspection. No delay of returning to the office computer. Each inspection point numbered tag has a QR code that identifies specifically with that point in the online system. We take location photos and assign an index page to each named facility location for easy follow-up in the report. All of vital information you are used to seeing on the report is linked. Inspection date, pipe size, wall thickness and variance percentage compared to new assessment will help your crew work with confidence. Contact us today to learn more about our integrated approach 1-800-218-7450.Contact Acuren For Ammonia System Inspection Services

With Acuren, you can receive expert ammonia system inspection services without disturbing insulation or disrupting your day-to-day operations. As a testament to our dedication to quality, we provide video and digital images of inspection results that clearly and easily show areas of concern to quickly take action on. Contact us online to get in touch with an Acuren representative about our ammonia system services, or call us at 1-800-218-7450. Brochure Download

Brochure Download Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →