Summary

Irving Wallboard is a highly automated, 300,000 square foot manufacturing facility that provides a broad range of gypsum wallboard products for use in the construction industry. This Saint John facility is one of the newest and most modern wallboard manufacturing facilities in North America. Acuren provides monthly Condition Based Monitoring services, whereby CBM Specialists will visit the plant to collect, measure and analyze vibration data on 100 of their assets. This monthly monitoring uncovered a bearing fault that would have remained undetected until a costly failure occurred. This discovery enabled Irving Wallboard to plan a shutdown and repair.

The Challenge – When Visual Inspection Isn’t an Option

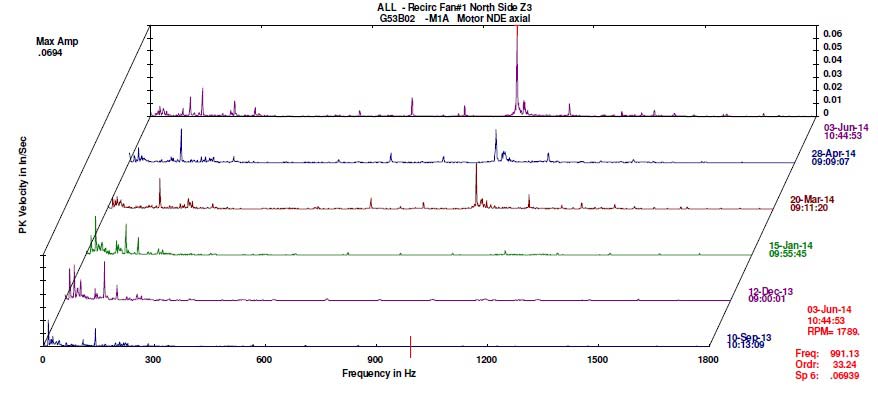

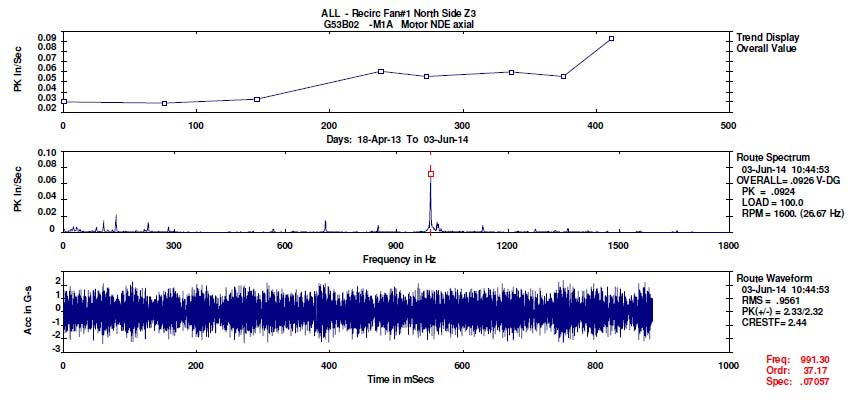

Each month Acuren Condition Based Monitoring Specialists collect machinery vibration and structure borne ultrasonic data as part of the regular condition monitoring program at Irving Wallboard. Many of the assets in this facility are positioned in such a way that visual inspection is difficult or impossible. The collection and analysis of dynamic vibration measurements provides the critical data required for maintenance and shut down decisions and planning. The data collected resulted in a recommendation to change the motor on this recirculation fan.

The Methodology – Data and Diagnosis

Trained and experienced technicians interpret the data collected, and make recommendations to the site maintenance teams based on findings of criticality and failure risk. The CBM technicians work as a member of the client’s team to identify and diagnose potential failure conditions before they result in unplanned outages. This motor was destined to fail if left undiagnosed.

The Value – Proactive Detection Prevents Costs of a Failure

The maintenance crew was able to replace this motor during a planned outage based on the findings from the monthly monitoring program. Had this motor been left undiagnosed and left in operation until failure, Irving Wallboard estimates that cost to the business would have been approximately $100,000.