Combatting Flange Face Erosion and Corrosion with Advanced PAUT Solutions

In oil and gas operations, where unsafe practices can lead to costly failures, flange face erosion and corrosion pose critical threats. These issues compromise refinery infrastructure, turning small flaws into major liabilities. With each flange connection vital to pipeline integrity, failures can cause leaks, unplanned downtimes, and lost revenue. This case study highlights strategies to combat these hidden dangers, ensuring safety, efficiency, and uninterrupted energy flow for global markets.

Unparalleled Execution In The Rope Access Light Mechanical Space

Our client, a chemical plant located in east Texas was struggling to have a particular rope access scope of work completed by another provider. When it became clear that progress was falling further behind schedule, and the provider requested more money and time to complete, the client decided to terminate that arrangement. Acuren’s competitive bid was selected to finish the remaining work which included installation of insulation/jacketing on head of vessel, 9 rings, transition and 19 pipe support areas on a 230’ tower utilizing rope access.

Solution Brief – Acuren Partners with An Energy Leader to Provide Access Solutions

Acuren partnered with an energy company to support their TA/Maintenance program. Acuren's access planner worked with the client's planning and execution team to review any work scopes that could be executed via rope access instead of scaffolding to reduce the overall time and cost.

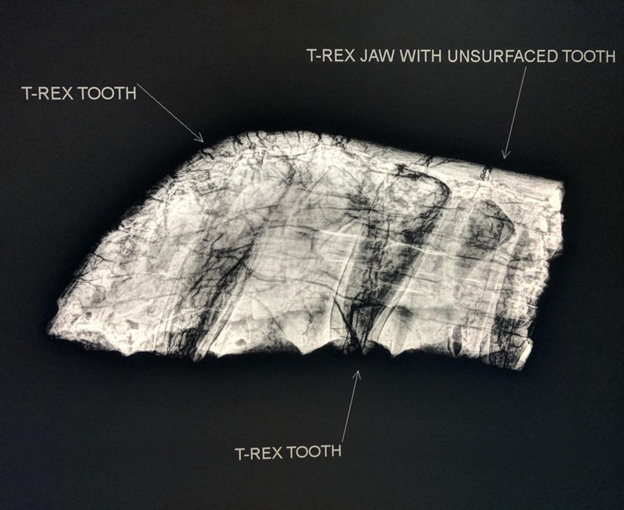

Acuren Helps American Paleo Find and Preserve Fossils

Acuren’s experts partnered with Ohio’s American Paleo to find and preserve fossils using computed radiography (CR). Acuren was tasked with radiographing soft shale, calcite and pyrite, to locate fossils. Our team was able to successfully and safely utilize computed radiography’s benefits over traditional methods to complete the project.

Solution Brief – Out of the Box Engineering Solution Saves Months of Time

Engineers, field technicians and NDT experts collaborated to find a suitable technique based on the engineer's unique idea which saved time, cost and increased reliability.

Acuren’s Experts Complete Project at Extraordinary Run Rate

Acuren’s Raleigh, North Carolina team just safely completed a project in less than four days which consisted of 250,000 conventional UT readings for a power industry client. The project was swiftly executed thanks to our experts strategically planning the major outage inspection as part of a shutdown.